TRUCK WEIGH IN MOTION

The Vehicle weight , not the numbeer of axles,determines wear and tear of roads.Toll authorities now use weight-based tolling,which relies on weigh-in-motion technology to determine the proper toll classification while keeping the traffic moving.

Its rigid construction significantly improves scale reliability in heavy-duty operation and helps to archieve precise positioning into the road during installation thus redusing the installation costs.The Weighbridge is connected to traffic lights and signals horn to control vehicle movement.Video camera for vehicle detection and vehicle image capturing can be delivered as optional equipment.

- Features

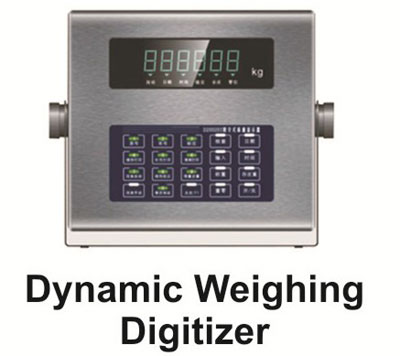

- Weigh In-Motion Processor

- Key Benefits

- Specifications

CLOSE COUPLED AXLES : The platform has been specifically designed to take all combinations of axles. Single axles, tandem and tri-axle combinations are easily weighed because the electronics can capture the weights of every axle individually. Close coupled axles with spring or air suspension are no problem to the weighbridge which will take individual axles of up to 30 Ton each

LAW ENFORCEMENT : A range of indicators and computer software is available for the EAGLE Axle which allow authorities to choose the best system for their enforcement needs. The Axle is particularly suited to where compliance with legislation is important as ‘overspeed’ weights are automatically detected so that vehicles cannot be presented with incorrect weighing tickets. The policy of EAGLE is to produce only top quality products incorporating the latest technological advances. Particular emphasis is placed on product reliability and durability and so the company undertakes all its own design and manufacture in order to maintain the essential high level of quality control.

DYNAMIC WEIGHING : In-motion (dynamic) weighing is an established feature of axle weighing and was originally developed by EAGLE in the early 1991s. It is the basis of the Single Axle system and today with modern, state of the art electronic circuits it provides the highest accuracy for weighing individual axles. As a vehicle drives over the weighbridge in low gear the axles are automatically recorded on the move. The electronics calculates the actual weight of each axle as it passes over the platform and immediately displays the weight. Automatic operation of the weighbridge allows a driver to weigh without the need for a specialist operator to be present. A unique electronic zeroing system ensures that the correct weight is achieved for each axle and that zero adjustment between weighing is not required.

The W.I.M processor is the heart of the weighing equipment. The signals from the weigh platform are connected to the W.I.M processor. A high speed processor is used to process the data and to respond to the instructions from the main computer. The output of the W.I.M processor is connected to the computer. The weighing software from the computer will interact with W.I.M processor and the complete data of the vehicles is recognized. The Following data of the vehicles is generated

- The total weight of the vehicles

- Each individual axle weight/li>

- Numbers of axle of the vehicle/li>

- Data and time of vehicle passed on the weigh in motion scale/li>

- Images of the vehicle (if cameras are used)/li>

- The vehicle number plate can also be recorded along with the weight data

- Number of vehicles passed on the weigh in motion scale Speed of the Vehicle

- Instant check for road legal weight

- Fully unattended weighing operation

- Weighs hundreds of vehicle daily

- Daily reporting measures vehicle productivity

- Automatic recording of weight and images of vehicle

- Gross weight,axle weights,numbers of axles can be recorded

- Data record can be stored for stored for future use or can be sent via LAN or Internet to the Server

OPTIONAL :

We can provide as optional on line cameras which can be fixed above the platform to have images of the trucks passing on the platform. These images can be used to know the vehicle numbers and the type of vehicles. A hard copy of the images and the vehicle weight combined together can be a proof tor the type of vehicles and the weight carried by the vehicle. These data will be important information of the vehicle passing through the check post, octroi nakas, overload of the vehicles, sales tax and excise departments, forest department etc.

| Maximum axle weight | 40 Ton |

| Maximum gross weight of vehicle | 120 Ton |

| Static accuracy | +/- 20 kg |

| Dynamic accuracy | +/- 50 kg per axle or +/- 1% to 2% whichever is The lesser. |

| Indicator resolution | 10 kg |

| Speed of operation | up to 10 km/hr (max) |

| Recommended | 3 to 5 km/hr |

| Power requirements | 230 v ac; 50 hz |

| Platform dimensions | 3.2 x 0.7 x 0.3 mtr |

| Platform type | welded construction, mild steel epoxy coated |

| Load Cells | 20 Ton capacity each, tool alloy steel, Sealed To IP68 |

| Electronics | Microprocessor weighing control sealed to IP68 |

| Approach and exit roadways | 20 meters (min) |

| Operating temperature range | -10 degree to +60 degree |